From the preparation of the substrate to the final surface finish, the STEULER Q7 System features a precisely coordinated sequence of compatible layers and work steps that prevent leaks and other of types of damage from ever developing. The STEULER Q7 System offers customers, planners and architects a reliable basis for every imaginable shape and design feature in the swimming pool.

The epoxy resins used enable the creation of a monolithic layer that satisfies all the physiological requirements for surface materials in the swimming pool construction sector. Whether it is used to waterproof pools for tiles, porcelain stoneware slabs, ceramic mosaics, glass mosaics or natural stone products, the STEULER Q7 System meets the requirements of any combination and geometry. Systematically coordinated size formats, mouldings and accessories together with exciting colour combinations give free reign to the imagination in creating never-before-seen pool architecture.

Thanks to its flexibility and predictable handling, the STEULER Q7 System is the system of choice when it comes to rejuvenating a pool as part of a comprehensive refurbishment.

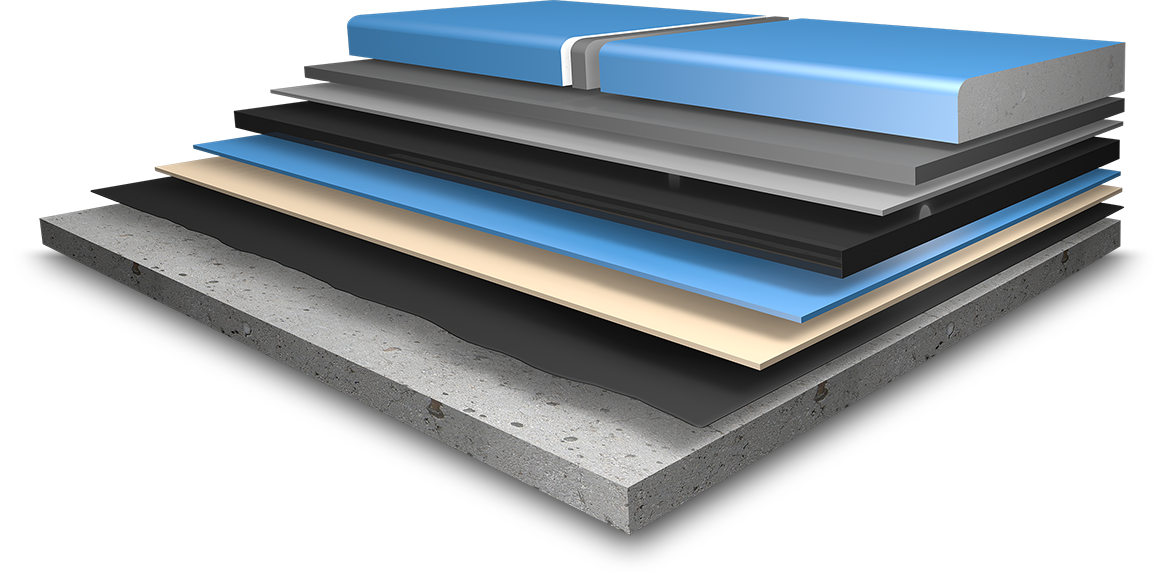

Whether for a new facility or a renovation project: Precisely matched layers make the STEULER Q7 system the favorite for safe swimming pool waterproofing.

First, any weak or loosely attached layers are removed from the concrete substrate by milling and sandblasting. This is a prerequisite for creating a firm bond with the rest of the system or for cementing levelling courses and fine profiling layers, such as screed or plasterwork.

The application of an electrically conductive epoxy resin filler in the pool and poolside areas serves as a base for the subsequent rubber sheet system. The filler layer also enables a reliable high-voltage leak test to be performed on the sheet using an electrical resistance meter later on.

This primer ensures that a firm bond is achieved between the epoxy resin layer and the subsequent elastomer layers.

The self-vulcanising cold adhesive firmly bonds the subsequent rubber lining with the substrate and is applied to the entire surface of the rubber strip and the epoxy-resin-primed substrate.

The tried-and-tested 2-mm-thick bromobutyl rubber waterproof sheet is at the heart of the waterproofing system. Apart from its great elasticity and tensile strength, it exhibits a high level of resilience as well as impermeability to steam and gas. The rubber strips are applied using various steel rollers in order to prevent the formation of air pockets.

Following leak testing, an epoxy-resin-based adhesive and sealing putty is applied in order to protect the waterproofing strips.

The various surface materials are laid and grouted in physiologically innocuous epoxy resin. Material combinations using porcelain stoneware, mosaic, glass mosaic and natural stone products are reliably accommodated and offer an almost infinite number of design possibilities.

Every one of the perfectly coordinated layers fulfils a specific function. Only when combined in this way do they result in a system that is greater than the sum of its parts: The STEULER Q7 System stands for greater flexibility, enabling even the trickiest of shapes and detail elements to be reliably sealed. For faster project execution with a truly reliable leak detection test. Greater peace of mind - reliable by design.

The STEULER Q7 System offers key benefits for you too:

The STEULER Q7 system delivers what it promises. In order to remain safe and leak-proof for many decades, we rely on the combination of high-quality, field-proven materials and well-trained specialists when installing the system. Each of the seven processing steps is carried out with the utmost precision and craftsmanship. Here we give you a small insight into the processing.

Flexibility - Durability - Reliability. Our experience as one of the world's leading lining specialists means the materials' system used is precisely tailored to the specific requirements of the swimming pool construction industry. The key component is a highly tear-resistant, 2 mm thick bromobutyl rubber sheet, which can be formed to fit every shape and pool geometry and provides for reliable, system-compatible waterproofing of every area of the pool, poolside areas and fittings.

Great care and skill are needed when bonding the waterproofing strips, especially in the critical areas where fittings, steps and edge profiles are incorporated. This is work we entrust to our trained installation specialists, who handle the material according to the best working practices for rubber membrane technology. Because achieving a watertight result requires competence, experience and meticulous care - down to the smallest of details. To ensure you are just as satisfied in 20 years as on day one.

The STEULER Q7 system is tested for impermeability in the pool and poolside areas before the final surface is laid. The electrically non-conductive rubber waterproof strip is subjected to a non-destructive leak test using a special high-voltage testing method in accordance with DIN 28055-2 that exploits the properties of the conductive priming filler layer. This reliably detects any imperfections or damage to the waterproofing layer, which can then be repaired in a system-compatible manner. This avoids having to leak test using the time-consuming and relatively unreliable method of filling the pool with water, resulting in valuable time savings for the remaining construction steps.